The Critical Role of O&M in Energy Management and Decarbonization

April 4, 2024

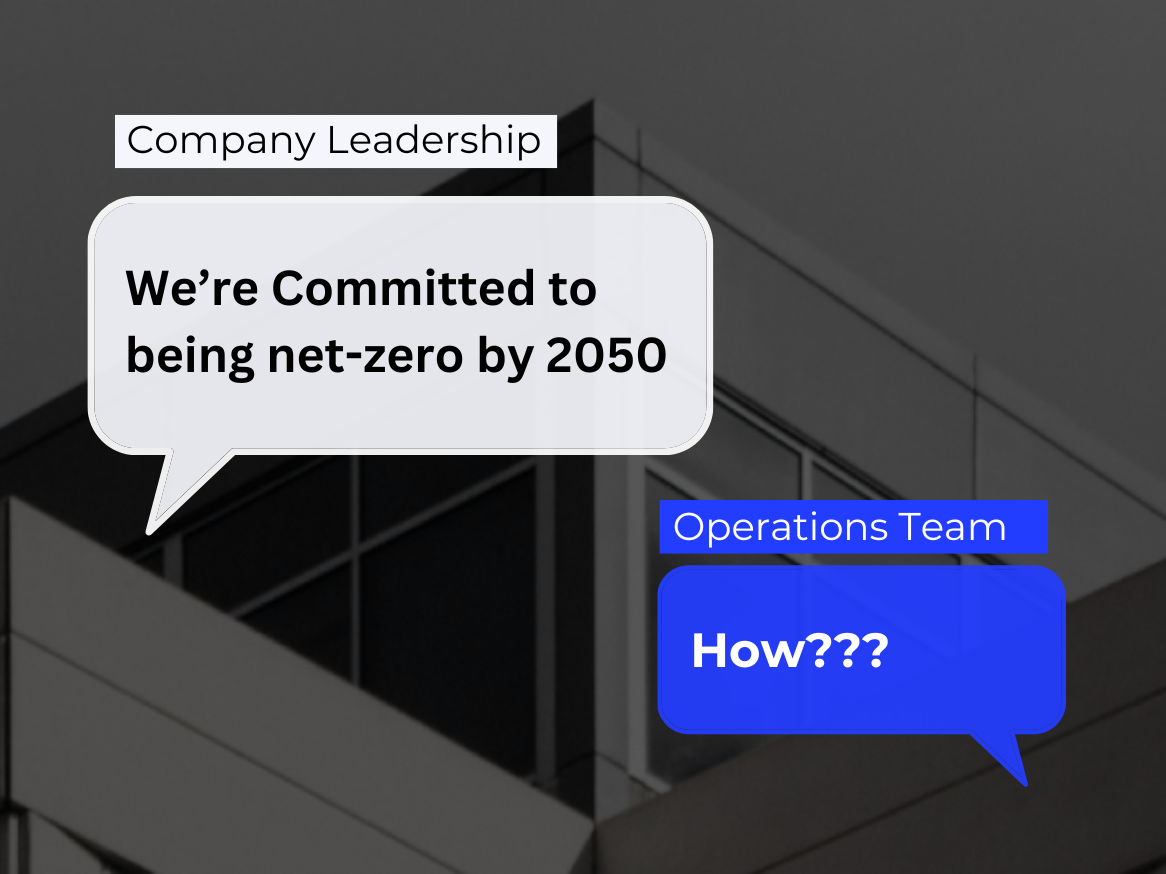

There are many facilities organizations wrestling with multi-decade plans to achieve net-zero and decarbonization targets. Often, these energy management goals are driven by significant capital project evaluations. How are we going to decarbonize our gas consumption on campus? How can we shift our electrical loads to renewable generation? While, of course, these large-scale capital projects are essential, we also know that the best-designed decarbonized systems will be a lot costlier if we are under-resourced on the operations side. At Clockworks, we often refer to this as driving facilities with the gas and the break on at the same time.

Building equipment degrades. Mechanical components break. Sustainable systems can start to run inefficiently. Sustainability and decarbonization plans cannot be successful if they don’t consider the day-to-day operations of equipment and facilities, or the savings that fixing those inefficiencies can drive.

In other words, Operations & Maintenance (O&M) needs a seat at the decarbonization table. and they need the tools and resources to continuously monitor and prove energy impact. Fault Detection and Diagnostics (FDD) is the enabling technology that calculates the carbon impacts of maintenance activities every day.

The fact is, O&M teams are fixing issues every day that have an impact on CO2 consumption. That leaking valve impacting comfort and triggering a “hot/cold call” just got fixed and saved ____ tonnes of carbon. That outdoor damper that needed to be fixed to prevent a critical freezing coil issue also just improved economizer efficiency and saved _____ tonnes of carbon. The reason for the blanks is that it’s not easy to calculate the impact of daily maintenance work order completion, and it’s not practical to pay for an engineering study to create reports on fast-moving, dynamic maintenance impacts on an ongoing basis.

Fortunately, best in class FDD software can AUTOMATICALLY calculate the carbon impacts of these maintenance efforts every day.

When O&M can report on the impacts they are having against longer-term sustainability goals, it becomes apparent that the lowest cost option for CO2 savings in any portfolio is FDD-driven maintenance. It truly is the low hanging CO2 fruit that never stops growing.

Of course, this is not new information that reducing energy consumption by improving efficiency at the operational level is essential to any energy management strategy. However, in the new world of decarbonization, every kWHh and kBTU of energy reduced is not only savings to the bottom line, but energy that now does not have to be decarbonized in the future

Let’s dig into how FDD helps to enable strategic energy management in Operations and Maintenance.

Fault Detection and Diagnostics in Energy Management

Many facilities leaders are turning to fault detection and diagnostics software to bring energy management into their maintenance workflows. Also known as building analytics, this type of facilities management software plugs into the building automation system and helps reveal hidden energy waste and prioritizes maintenance issues so technicians can focus on resolving issues that are consuming the most energy.

FDD detects energy inefficiencies in real-time and lets building teams monitor building performance remotely. This allows teams to quickly identify the equipment wasting energy and address the issue early, minimizing energy waste. Instead of waiting to see an energy spike in a utility bill, FDD software gives you a front-row seat to see how building systems are operating.

Tracking Energy Use & Optimizing HVAC Systems

For example, building analytics software can identify equipment that is running outside of normal occupancy patterns. It can pinpoint AHUs that aren’t economizing under the right conditions or if they’re not using heat recovery, causing you to miss out on “free” energy opportunities. Or it can look at low loop loads to reduce pump speeds.

Using energy usage data to set system controls is an easy way to immediately improve a building’s energy efficiency.

Additionally, building analytics software can optimize your HVAC systems by pointing out deviations in temperature setpoints, ventilation rates, and airflow based on occupancy patterns, weather conditions, and other variables. It can also be used to measure comfort performance and reassure stakeholders that comfort is not being compromised while trying to save energy.

Especially on HVAC systems, FDD can show when equipment is not resetting as expected to save energy. And after maintenance work is complete, FDD can be leveraged to show the impact of repairs and confirm that the system is running at optimal levels.

Not only does energy efficiency at the HVAC level support greater sustainability goals, but it also delivers significant cost savings. At the University of Iowa, the facilities team implemented Clockworks Analytics’ fault detection and diagnostics (FDD) software to deliver $2.5 million per year in verified energy savings. Read the blog post here.

Developing an FDD-Powered Energy Management Program

Building analytics makes it possible to benchmark your building performance to better understand energy consumption, monitor performance continuously, and verify cost and carbon savings from maintenance and operations activities.

Below is a step-by-step guide to driving energy management in operations:

- Make a Commitment

The first step is to make a commitment to an energy management program. If you’re reading this, it’s likely you’ve already set this goal. This will require the use of energy meters, sensors, and building automation systems to collect real-time data on energy use—including data from HVAC, lighting, electrical equipment, and other relevant sources. Operations plays a critical role in being able to achieve energy goals at the organizational level.

This commitment must include the operations team and account for the procurement of the FDD technology that will enable day-to-day energy monitoring within operations.

2. Assess Performance & Set Goals

If you’re like most facilities teams, you’re already overwhelmed by BAS alarms and drowning in a backlog of preventive maintenance. The initial reaction we often hear is, “How do I deal with energy management issues on top of all my other priorities? How do I prioritize this request against a routine boiler maintenance or occupant hot call complaint?”

This is a two-pronged approach.

A top-down “macro” view of performance coupled with a bottom-up specific list of items that need addressed. FDD software can automate both. The Energy Insights Dashboard below is an example of a top-down view that can benchmark the actual energy consumption of a building or portfolio down to a meter and identify patterns and energy consumption, as well as normalize this data across many connected buildings.

That way, you can understand your organization’s baseline and what specific goals can be set such as reducing electric and gas consumption by xx percent.

An Energy Management Information System (EMIS) with FDD capabilities like Clockworks provides an easy way to get a holistic view of energy performance across a building or portfolio.

According to the Smart Energy Analytics Campaign—which produced the largest dataset on Energy Management and Information Systems (EMIS)—organizations that incorporated Fault Detection and Diagnostics software into operations drove a median annual energy savings of 9%, the highest of the group

FDD also provides the bottom-up view. It lets users go beyond the meter or utility bills and quickly identify the highest-priority issues consuming significant energy. Energy waste can be identified in real-time at the individual equipment level and help technicians determine the root-cause of these issues.

The power comes in combining these two approaches. It enables us to set clear goals based on overall performance and create a plan that can be actioned.

3. Create and Implement an Action Plan

An effective energy management program blends energy goals with operational and maintenance priorities. The key is integrating these new energy tasks into the existing operational workflows and priorities that the operation team is dealing with every day.

How does this issue with high energy impact get prioritized against equipment with reliability concerns or comfort issues that occupants are going to complain about? FDD provides a holistic view that normalizes performance across these three categories so the operations team can create a combined list of work orders to action.

When the energy targets and net zero goals are translated to work orders, the operations team can prioritize them against the other operational priorities and drive the work order activity to meet all these goals.

Then, it’s just about leveraging the FDD tool to create an action plan. The beauty of FDD is it allows you to create a plan at scale. Across hundreds of buildings and potentially thousands of issues, you can drill down into the top ten energy issues.

It’s not about including everything possible, but rather creating an ongoing process to continually review these top ten issues and incorporate them into the operational priorities. This way we can address them piece by piece on a day-to-day basis.

Once the action plan has been created, it’s now about implementation. And that’s where FDD can really help. From the prioritized list of actions, you can drill down to view root-cause diagnostics, removing time-consuming analysis and delay after seeing a spike in energy. Now, your team can immediately fix the issue and save energy.

All the findings, data, and graphs are within the diagnostics report, eliminating the need for an engineer to spend hours looking at trends and manually analyzing the issue.

Finally, the most important piece is being able to take action. Clockworks translates these diagnostic findings into work orders that integrate into the operations team’s existing workflows.

4. Evaluate Progress

Building analytics software can validate that specific issues were fixed and quantify the savings impact of each completed work order. There’s no longer room for ambiguity on the utility bill or hope to meet the energy reduction goal, but clear measured savings associated with each work order.

Clockworks automatically calculates energy waste, carbon, and energy costs to then track against your energy reduction goals, including extremely accurate Measurement & Verification (M&V). This makes it easy to review and report on progress to make sure stakeholders are continuously aligned and informed.

5. Continuous Monitoring and Optimization

FDD allows you to continuously monitor energy consumption and performance metrics. The reality is, things break every day, valves keep leaking, dampers keep sticking, and sensors keep degrading. Even with traditional retro-commissioning, drift is inevitable and you are always fighting to return to baseline.

FDD provides monitoring-based commissioning to immediately address energy issues instead of waiting for a retro-commissioning event.

Fault Detection and Diagnostics is used across stakeholders to prioritize and action the issues uncovered to keep energy waste as low as possible and perform at its peak state.

Fault Detection and Diagnostics is the Key to Holistic Energy Management

Over time, these impacts become very significant. The regular routine of working through the top ten issues daily, weekly, or monthly and eliminating energy waste results in tremendous year-over-year energy savings.

Just look at this example from the University of Iowa:

Just as importantly, FDD improves the efficiency of your team. They can continue to focus on the highest impact work rather than spending time addressing unexpected breakdowns and equipment failures.

###

Back to blog