The Clockworks

Information Model

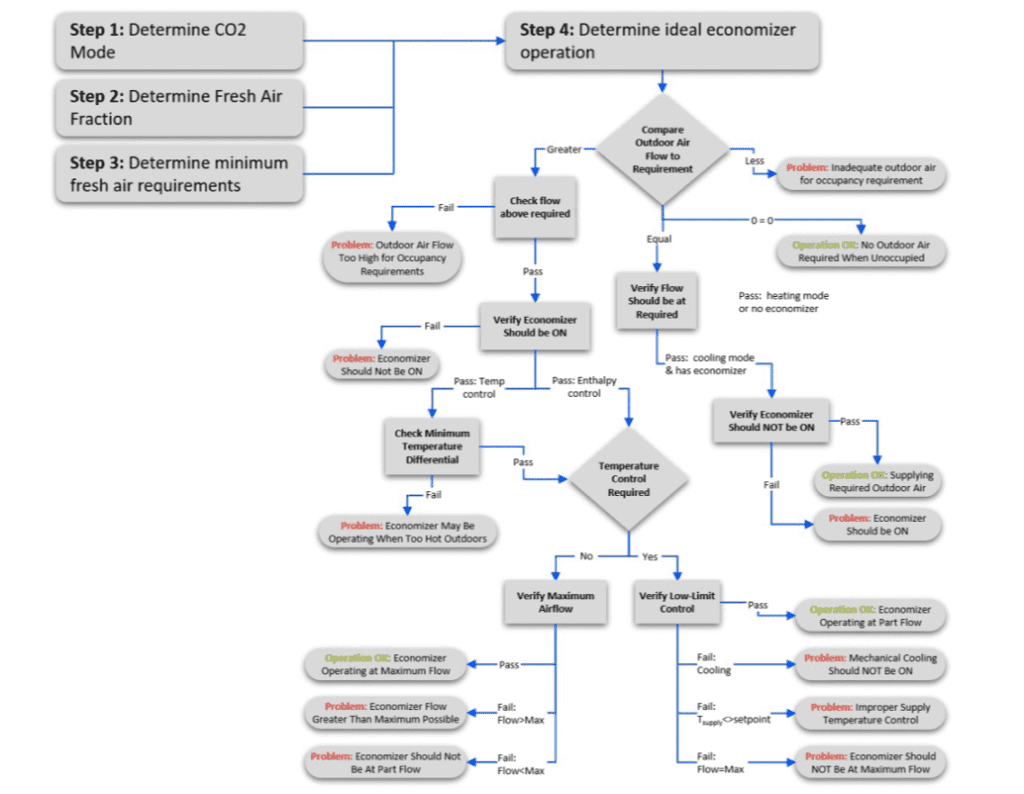

The most critical piece of fault detection and diagnostics is its “brain”— the Information Model that analyzes the BAS data and produces the diagnostics that your team will use to drive energy and operational savings.