The Condition-Based Revolution: Leveraging Fault Detection and Diagnostics for Operational Excellence

June 6, 2025

By: Nicholas Gayeski, Clockworks Analytics Co-CEO

Modern facility management is undergoing a revolutionary transformation. Gone are the days when building operators could rely solely on reactive maintenance strategies and calendar-based schedules. Today’s most successful organizations are leveraging fault detection and diagnostics (FDD) to create intelligent, condition-based operations that optimize everything from maintenance priorities to capital investments.

Breaking Free from the Reactive Cycle

Traditional facility management operates in a perpetual state of reaction and lack of data. Equipment fails unexpectedly, energy costs spike, and people’s complaints are the first indicators or problems. This approach is not only inefficient but increasingly unsustainable in today’s competitive landscape.

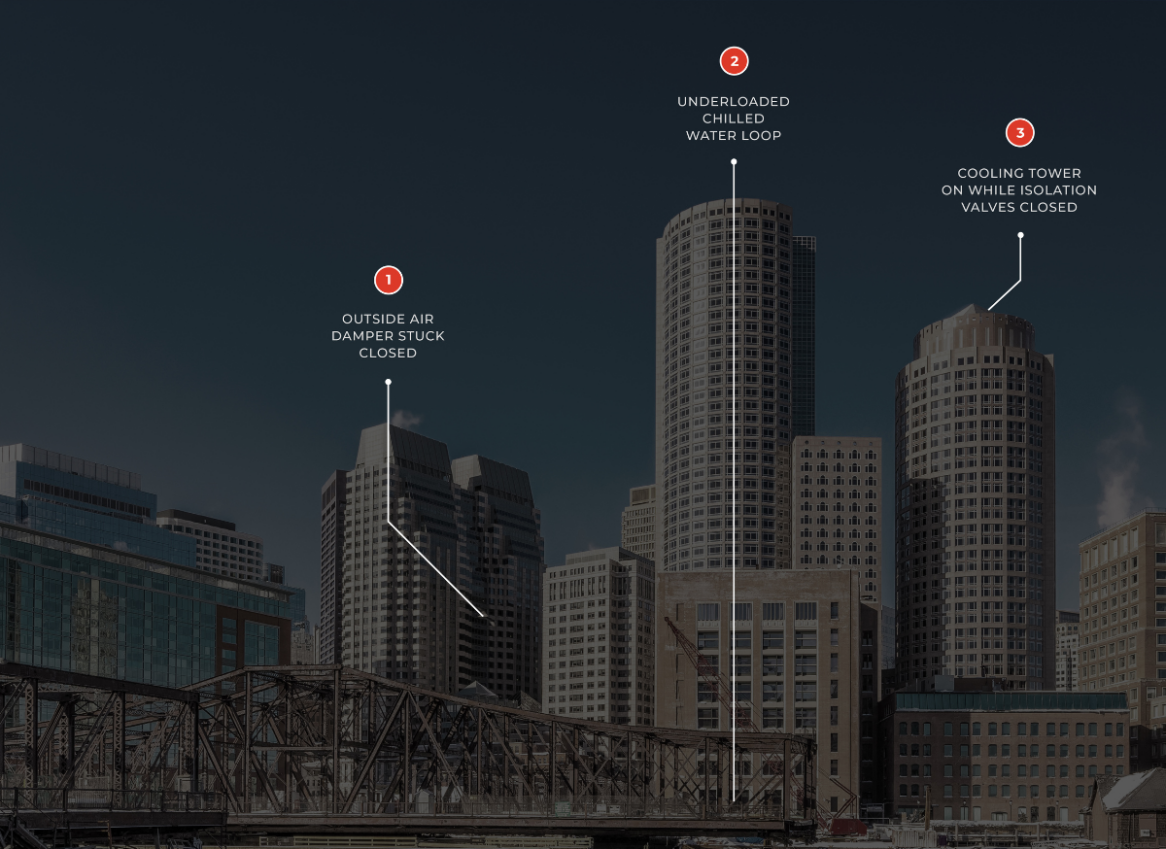

Fault detection and diagnostics represents the cornerstone of a new paradigm: condition-based management. By continuously analyzing thousands of data points from building systems, FDD solutions transform raw operational data into actionable intelligence that drives data-driven decision-making across maintenance, energy management, and capital planning.

The Power of Intelligent Asset Monitoring

Modern fault detection and diagnostics platforms, like Clockworks Analytics, go far beyond simple alarm systems. They create a comprehensive “system of record” for asset health, providing unprecedented visibility into:

- Mechanical faults and performance degradation

- Control and sensor issues that impact system efficiency

- Early warning indicators of potential equipment failures

- Energy inefficiencies and optimization opportunities

- Reliability risks across critical building systems

- Equipment wear patterns and performance trends

This deep operational intelligence becomes the foundation for smarter decisions across your entire facility management lifecycle.

Revolutionizing Maintenance Through Condition-Based Strategies

One of the most immediate benefits of implementing fault detection and diagnostics is the transformation of maintenance operations. Instead of following prescribed, calendar-based schedules, maintenance teams can respond to actual equipment needs and performance data.

This condition-based approach delivers tangible benefits:

- Optimized technician productivity through targeted maintenance activities

- Proactive fault prevention before minor issues become major failures

- Elimination of unnecessary maintenance tasks that waste time and resources

- Higher first-time fix rates through better diagnostic information

Consider the common practice of quarterly filter changes. With performance data from fault detection and diagnostics, facilities can optimize filter replacement schedules based on actual conditions—servicing some systems monthly while extending others to semi-annual schedules. This data-driven approach simultaneously reduces costs and improves indoor air quality.

Smart Capital Planning Through Performance Analytics

While many organizations still base capital planning decisions on visual inspections and equipment age, fault detection and diagnostics enables a more sophisticated approach. Performance-based capital planning leverages actual equipment health data to:

- Extend useful equipment life when systems are performing well

- Prioritize replacements based on real performance degradation

- Build performance specifications into procurement processes

- Justify ROI with clear operational cost data

Imagine confidently stating, “This 15-year-old air handling unit is still performing optimally—we can safely delay replacement for 5-7 years.” This level of confidence comes from continuous performance monitoring through advanced fault detection and diagnostics.

Bridging Energy Management and Maintenance

Traditional facility management often treats energy and maintenance as separate disciplines. However, fault detection and diagnostics reveals the critical connection between equipment health and energy efficiency. Well-maintained equipment consistently operates more efficiently, creating opportunities for:

- Real-time efficiency monitoring and optimization

- Targeted energy interventions based on performance data

- Measurement and verification of energy savings initiatives

Expanding Impact Across Facility Operations

The benefits of fault detection and diagnostics extend throughout facility operations:

- Space Utilization: Match HVAC system capabilities with actual occupancy patterns and loads rather than design assumptions.

- Occupant Comfort: Prevent comfort complaints by identifying and addressing issues before they impact building users.

- Sustainability Management: Enable operational changes to contribute meaningful progress towards sustainability initiatives.

- Vendor Management: Transition from time-based service contracts to outcome-based agreements supported by performance data.

- Risk Management: Proactively identify and address operational vulnerabilities before they impact business operations.

- Regulatory Compliance: Use continuous monitoring data to better comply with regulatory and operational requirements.

Implementation Success Factors

Organizations seeking to maximize the value of fault detection and diagnostics should focus on several critical success factors:

- System Integration: Connect FDD platforms with existing enterprise systems including CMMS, asset management, and energy management platforms.

- Workflow Redesign: Restructure operational processes around data-driven insights rather than traditional schedules and assumptions.

- Team Training: Ensure facility staff can effectively interpret and act on diagnostic information and performance analytics.

- Trust Building: Demonstrate value through transparency in reporting and measurable operational improvements.

The Future of Intelligent Facility Management

As building systems become increasingly complex and operational resources face growing constraints, the adoption of fault detection and diagnostics transitions from competitive advantage to operational necessity. These platforms represent more than fault detection tools—they serve as comprehensive asset intelligence systems enabling smarter decisions across every aspect of facility management.

Organizations that fully leverage fault detection and diagnostics to create holistic, condition-driven operations will achieve multiple simultaneous benefits: reduced operational costs, extended asset life, improved occupant experiences, and accelerated progress toward sustainability goals.

The question isn’t whether your organization should implement fault detection and diagnostics—it’s whether you’re prepared to embrace the condition-based future of facility management. The time to move beyond data-blind operations and harness the power of intelligent asset monitoring is now.

Want to dive deeper into the future of intelligent facility management? Watch our exclusive webinar recording featuring Clockworks Analytics Co-CEO, Nick Gayeski, as he explores how fault detection and diagnostics is transforming the industry. Discover real-world case studies, implementation strategies, and actionable insights that facility managers are using to revolutionize their operations.

Access the full recording now to learn how leading organizations are leveraging FDD to reduce costs, optimize performance, and stay ahead of the curve.