Condition-Based Maintenance

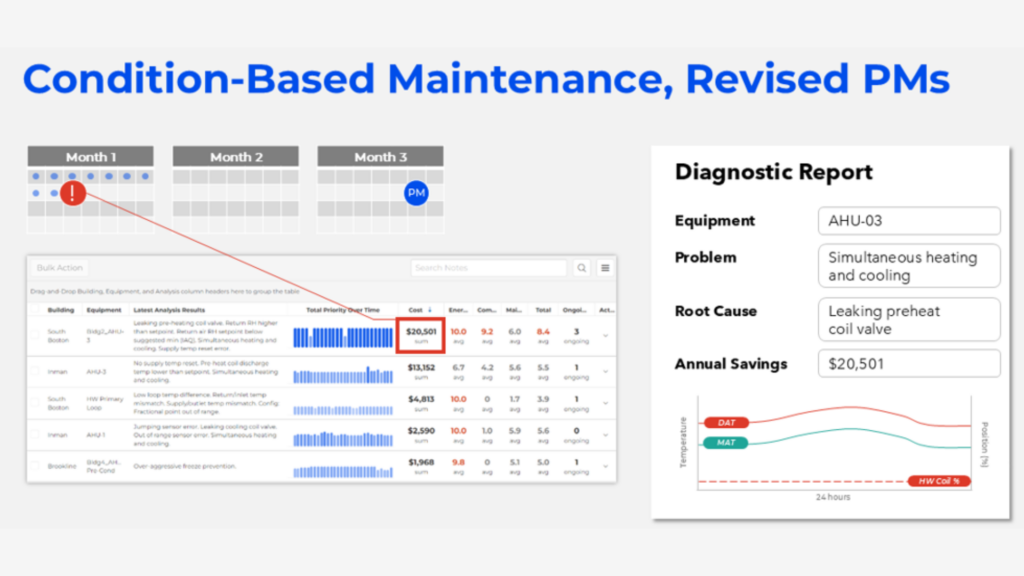

Condition-based maintenance (CBM) represents the evolution of facility management from reactive “fix-when-broken” approaches and rigid preventive maintenance schedules to intelligent, data-driven maintenance strategies.

Condition-based maintenance (CBM) represents the evolution of facility management from reactive “fix-when-broken” approaches and rigid preventive maintenance schedules to intelligent, data-driven maintenance strategies.

Instead of performing maintenance based on calendar dates or waiting for critical problems to be reported, condition-based maintenance uses real-time performance data to determine exactly when maintenance is needed based on its actual operating condition.

This approach relies on continuous equipment monitoring and predictive maintenance technologies to assess the actual health and performance of building systems, particularly HVAC equipment, allowing facility managers to make informed decisions about when, where, and how to allocate maintenance resources.

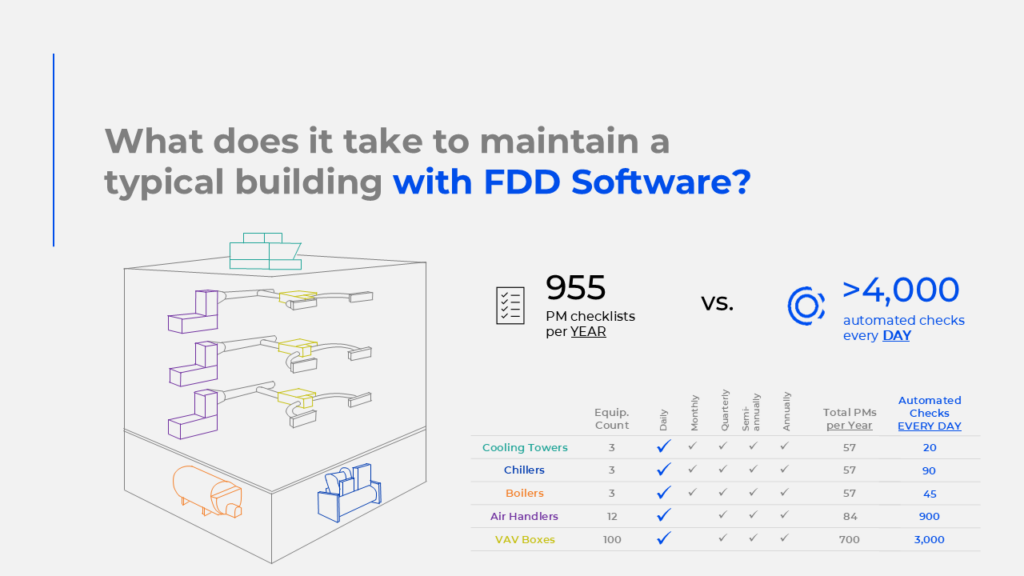

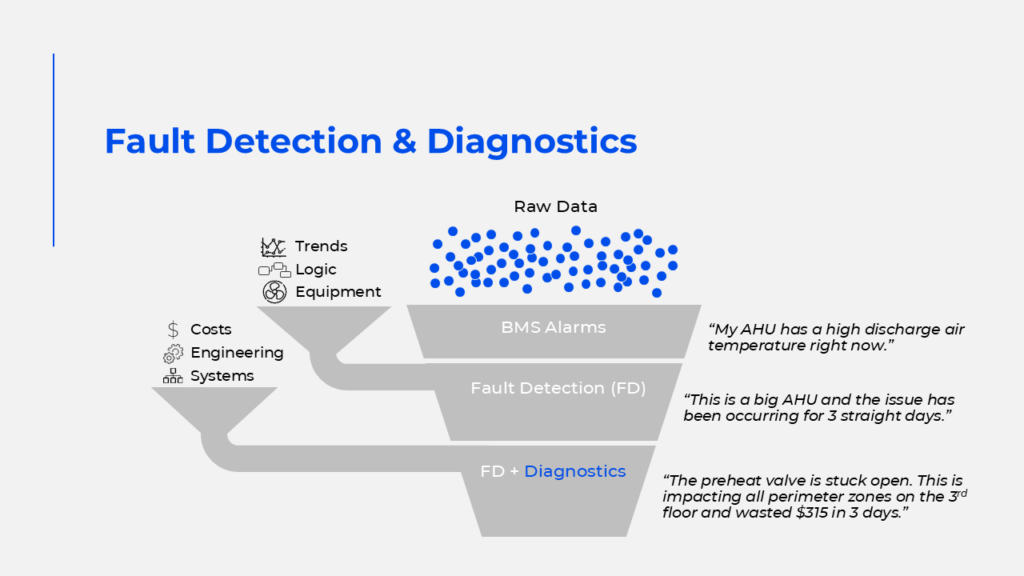

Fault Detection and Diagnostics (FDD) systems serve as the critical technology foundation that makes condition-based maintenance possible. FDD platforms continuously monitor thousands of data points from building automation systems, analyzing performance patterns to:

Identify when equipment operates outside normal parameters

Pinpoint specific issues causing performance problems

Forecast when components are likely to need attention

Rank issues by severity and impact on operations

Confirm that maintenance actions successfully resolved problems

Modern HVAC monitoring systems serve as the foundation for condition-based maintenance by collecting performance data 24/7. These systems track equipment runtime patterns, energy consumption metrics, and critical parameters like temperature, pressure, and flow rates. FDD platforms also monitor control system responses and sensor calibration status, creating a comprehensive view of equipment health that enables data-driven maintenance decisions.

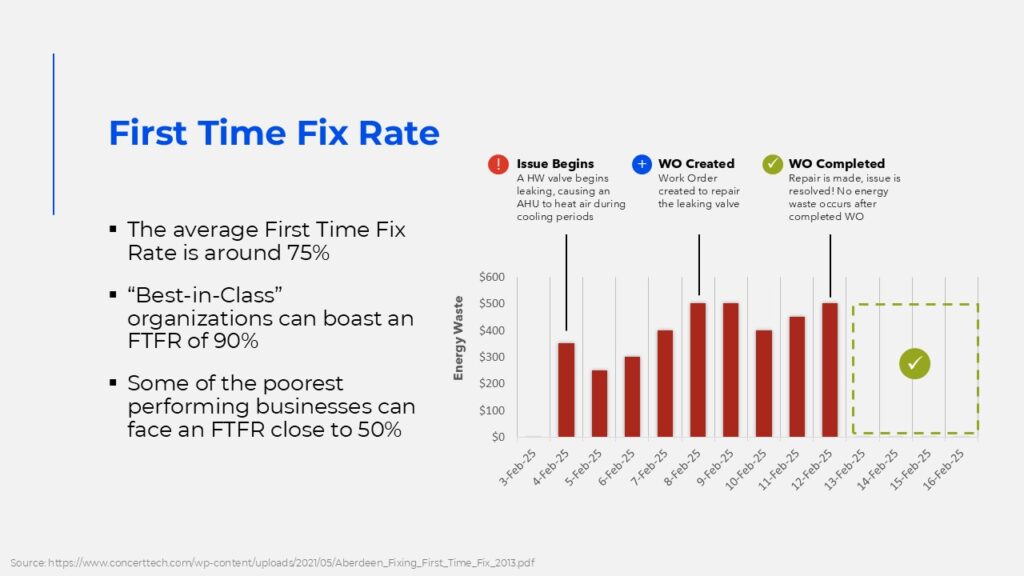

FDD algorithms transform raw data into actionable maintenance intelligence by identifying performance issues across multiple categories. The systems detect mechanical faults like stuck dampers and failing sensors, control problems such as incorrect setpoints and scheduling errors, efficiency degradation from dirty filters or fouled coils, and operational deviations like unnecessary runtime. This comprehensive fault detection capability ensures that maintenance teams can address problems before they escalate into costly failures.

Condition-based maintenance software intelligently ranks detected issues to optimize maintenance resource allocation. The systems prioritize faults based on energy impact, comfort risk, equipment failure potential, and safety concerns. This prioritization ensures that maintenance teams focus their efforts where they’ll deliver the greatest operational and financial benefits while addressing critical safety issues immediately.

FDD systems complete the maintenance cycle by validating repair effectiveness and measuring results. These platforms confirm that maintenance actions resolved identified problems, quantify performance improvements and energy savings, and provide ongoing monitoring to prevent issue recurrence. This validation capability creates a continuous improvement cycle that enhances maintenance effectiveness and demonstrates clear ROI for condition-based strategies.