Advanced Chiller Analytics: How Smart Monitoring Transforms Central Plant Performance

June 17, 2025

By Antoine Vandyck and Todd Addis, PE

The Challenge: Complex Chiller Systems Need Smarter Solutions

Commercial chillers are the workhorses of central HVAC systems, consuming massive amounts of electricity to produce the chilled water that keeps buildings comfortable. While the process may seem straightforward, managing it is anything but—especially in facilities with multiple chillers, variable loads, and complex control strategies. Even minor inefficiencies can lead to significant energy waste and equipment wear.

The problem? Many facilities face challenges in deriving actionable insights from their chiller data and maintaining a comprehensive overview of the entire cooling system. Traditional monitoring methods often burden operators with overly technical diagnostics, missing key opportunities to improve performance an reduce costs.

Chiller Analytics That Actually Work

Central Plant Performance: Beyond Basic Monitoring

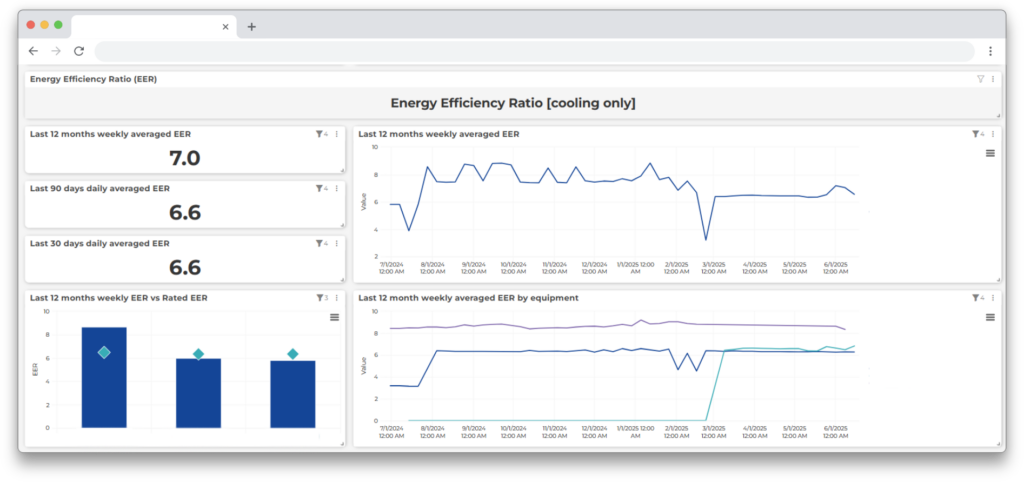

Modern chiller analytics platforms transform raw operational data into clear, actionable insights through sophisticated KPI dashboards. The core metric—tracking the ratio between electricity consumed and chilled water produced—provides facility managers with an immediate understanding of system performance.

Key efficiency tracking capabilities include:

- Real-time chiller efficiency monitoring: Compare actual Energy Efficiency Ratio (EER) against design specifications and historical data to benchmark the equipment together

- Temperature differential analysis: Monitor the differential between supply and return temperatures

- Multi-chiller optimization: When facilities operate multiple units, smart analytics ensure the most efficient chillers run at the most appropriate times

Operational Intelligence: Maximizing Equipment Lifespan

Beyond monitoring efficiency metrics, advanced chiller analytics provide operational insights that maximize equipment lifespan and minimize total cost of ownership through intelligent decision-making.

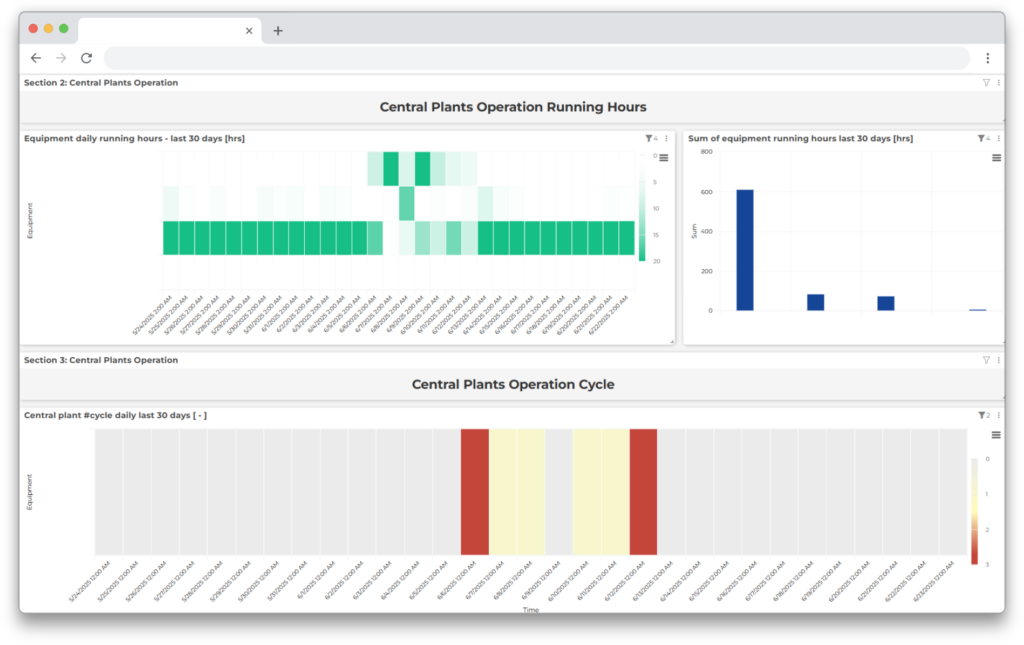

Strategic Equipment Staging When facilities operate multiple chillers, analytics platforms automatically determine the optimal combination of units to run based on real-time efficiency data and load requirements. This eliminates guesswork and ensures the most cost-effective equipment operates during each load condition, reducing wear on less efficient units while maximizing energy savings.

Predictive Maintenance Through Pattern Recognition Daily runtime heatmaps reveal equipment usage patterns over 30-day periods, enabling facility managers to distribute operational hours evenly across their chiller fleet. This data-driven load balancing prevents premature wear on frequently used units while identifying underutilized equipment that may need attention.

Short Cycling Prevention Frequent starts and stops (short-cycling) degrade performance and shorten equipment lifespan. Analytics identify the root causes—like incorrect setpoints or load miscalculations—so teams can resolve them before damage occurs.

Whole-System Optimization

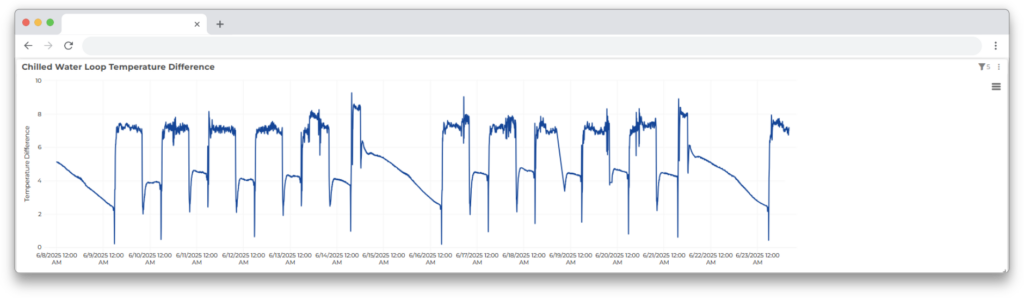

Chilled Water System Integration Effective chiller analytics monitor the entire cooling ecosystem, recognizing that chiller performance depends on proper water loop operation. Temperature differential monitoring identifies when return water temperatures are too high or too low—both conditions that force chillers to work harder and waste energy. By optimizing these differentials, facilities can achieve significant efficiency gains without equipment modifications.

Heat Rejection Optimization Cooling tower performance directly impacts chiller efficiency, yet many facilities monitor these systems separately. Integrated analytics platforms identify when cooling tower issues are causing mysterious chiller efficiency drops, enabling targeted maintenance that addresses root causes rather than symptoms. This systematic approach prevents reactive troubleshooting and reduces overall maintenance costs.

Precision Diagnostics: Where Complexity Meets Clarity

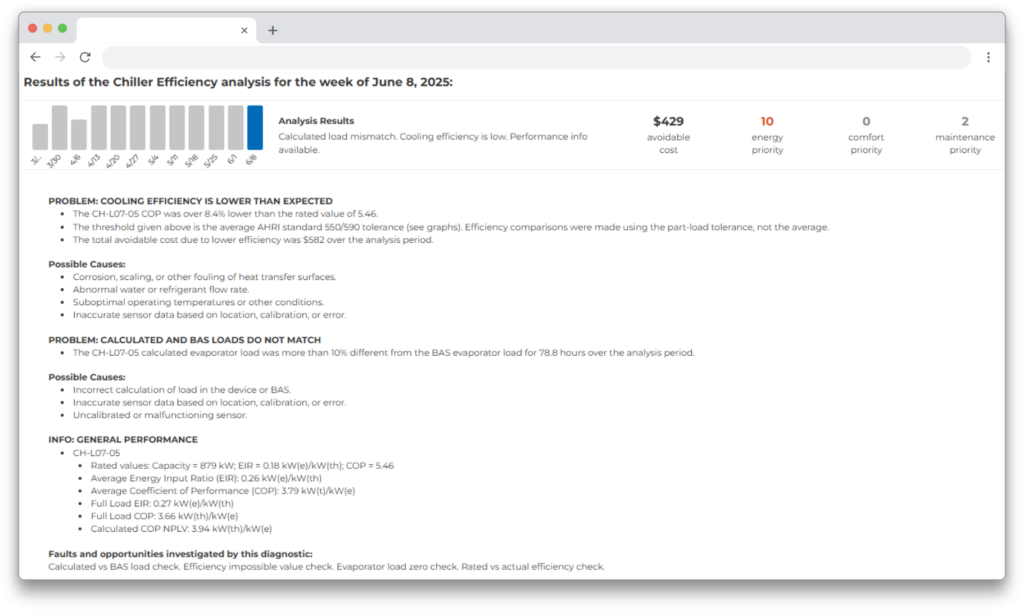

Clockworks Analytics fault detection and diagnostics solution performs comprehensive fault detection across 60+ diagnostic checks, monitoring critical aspects of chiller and heat pump operations. This sophisticated diagnostic engine automatically identifies issues that traditional monitoring systems miss entirely.

Comprehensive Flow and Valve Monitoring:

- Detects flow and pressure anomalies in evaporator and condenser

- Identifies valve position discrepancies and isolation valve conflicts

- Monitors differential pressure tracking across all water loops

- Flags minimum flow violations that can damage equipment

Advanced Efficiency Analysis:

- Tracks real-time chiller efficiency metrics and NPLV calculations

- Performs heat balance verification to ensure thermodynamic consistency

- Automatically flags when chiller efficiency drops below expected performance thresholds

Critical Temperature and Pressure Diagnostics:

- Monitors evaporator and condenser approach temperatures for optimal heat transfer

- Detects refrigerant pressure anomalies that indicate system stress

- Tracks temperature setpoint deviations that indicate suboptimal operation or proactive maintenance tasks

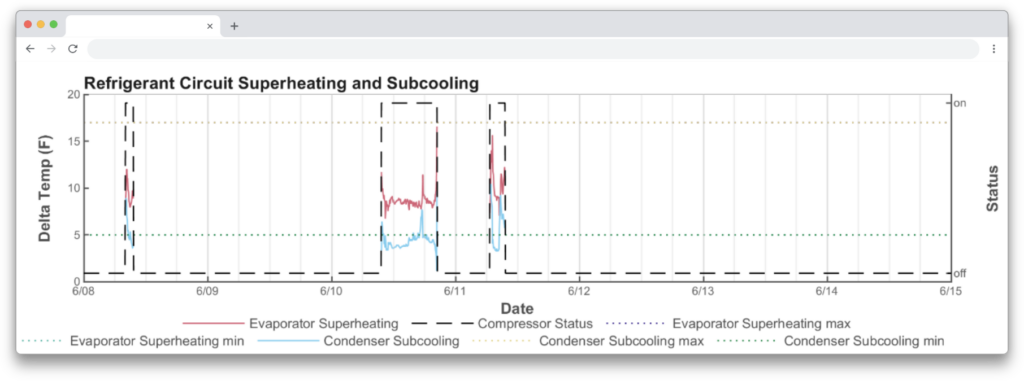

- Identifies superheating and subcooling issues that compromise life cycle

System Integration Monitoring:

- Detects equipment coordination problems (cooling tower fans running when chillers are off)

- Monitors free cooling valve operation and mode switching

- Identifies compressor staging operation improvement

- Tracks part-load performance issues

Each diagnostic check includes automatic cost calculation capabilities, transforming detected faults into quantifiable energy savings opportunities. When the system identifies efficiency degradation, it calculates the financial impact as avoided costs—turning abstract performance issues into concrete ROI justifications for maintenance actions.

Real-World Impact: Healthcare System Success Story

A leading healthcare provider exemplifies the transformative power of advanced chiller analytics across multi-building portfolios. By having implemented comprehensive monitoring across their campuses, their facilities teams now detect inefficiencies and identify faults before they can impact critical operations.

In healthcare environments, the stakes couldn’t be higher. Chilled water systems are critical in maintaining precise temperature and humidity control in operating rooms, sterile processing areas, and pharmacies—spaces where even minor environmental deviations can compromise patient safety, regulatory compliance, and quality of care.

The transformation has been remarkable:

- Proactive maintenance prevents system failures that could disrupt critical care areas

- Early fault detection eliminates costly emergency repairs and potential downtime

- Continuous monitoring ensures stable and compliant conditions in sensitive patient-care spaces

- Data-driven decisions replace reactive emergency troubleshooting with a more strategic approach to operations

This healthcare system shifted from crisis management to proactive operations and maintenance, improving energy efficiency while strengthening their ability to ensure safe and compliant healing environments. The result: enhanced system reliability that directly supports their mission of delivering exceptional patient care.

The Bottom Line: Measurable Energy Savings & Operational Efficiency

Advanced chiller analytics platforms deliver measurable results through executive-level reporting that tracks energy savings against established targets while enabling teams to maintain highly-reliable central plants in support of their buildings Facilities typically see immediate improvements through:

- Optimized equipment staging and runtime patterns

- Early detection and resolution of efficiency issues

- Data-driven maintenance scheduling

- Technician task prioritization based on energy impact

- Reduction in risk of downtime or impact to critical operations

Transform Your Chiller Operations Today

Modern facilities can no longer afford to operate chillers based on guesswork or outdated scheduling approaches. Advanced analytics platforms transform complex operational data into clear, actionable insights that drive measurable energy savings while optimizing equipment operation.

The question isn’t whether smart chiller analytics can improve your facilities—it’s how much energy and operational efficiency you’re losing by waiting to implement them.

Stop Playing Chiller Maintenance Guesswork

See how Clockworks Analytics identifies efficiency issues before they impact your operations—and your budget.