“Do You Do A.I.?” What Actually Powers Building Analytics.

September 10, 2021

When we explain Clockworks to prospective clients and partners, one curious question is popping up more and more:

“Do you do A.I.?”

Since artificial intelligence (A.I.) has gathered lots of buzz and transformed other industries in recent years, these types of questions are understandable. And our answer? It’s an emphatic YES… but it’s not what you might think.

To explain, consider this: most of the technological progress made in A.I. in recent years has been in machine learning, a subset of the broader A.I. term. And most of the progress in machine learning has been in deep learning, a subset of machine learning.

And while Clockworks does leverage some types of supervised machine learning, the kind of artificial intelligence that makes Clockworks cutting edge isn’t machine learning at all. In fact, it’s a type of A.I. that’s been around for decades: expert systems.

Inside the building industry, expert systems are not very well known or understood. For those less familiar, an expert system uses domain-specific knowledge and attempts to recreate the logic that a human expert in a given field would use if trying to solve a problem. Expert systems can be simple or incredibly complex based on the number of decisions being made within the system.

While expert eSystems aren’t new, they are the ideal technique for Fault Detection and Diagnostics (FDD) analyses. Any engineer that has ever picked up a thermodynamics textbook knows the engineering equations used to analyze building performance are well defined. You don’t need to train an entire machine learning neural net to learn thermodynamics. Expert systems (and the software platform they live in) allow you to apply those existing engineering principles to an automated analysis of building performance.

If you’ve ever tried to do your own tax return paperwork and used TurboTax, you know the value of an expert system. Taxes (at least in the US) are extremely complicated. But TurboTax guides you through the inputs and abstracts away that complexity step by step. It’s like a tax expert is looking over your shoulder as you go.

Put another way, an expert system is a computer system emulating and automating the decision-making ability of a human engineer, at scale. This is different from other types of A.I. (like machine learning) because it requires that expert’s knowledge—meaning you can only design an expert system for taxes if you understand how to fill out a return yourself. Ditto for HVAC FDD: you need to actually understand HVAC. A data scientist who understands algorithms but not HVAC will not be able to build it.

A System of Expert Systems

The team of intelligent humans at Clockworks (the “experts”) have been improving Clockworks’ A.I. for over a decade. And each new building that the artificial intelligence sees, enhances the expertise of the system. In fact, Clockworks is actually built as a system of expert systems that mimics a human’s analysis across all kinds of buildings and produces insightful decisions that support the FDD process, such as:

- Clockworks can infer an air handling unit (AHU) or other system’s configuration using only point types (i.e. we “build” a complex AHU including ducts, fans, coils, etc without requiring someone to actually model all that).

- Clockworks can infer a sequence of operations using point types alone, or in conjunction with a very small number of known equipment variables. For example, if an enthalpy point is there, Clockworks infers that the economizer is controlled based on enthalpy rather than drybulb or dewpoint. If an “RH Max” point is there, Clockworks infers that the unit has sequences for dehumidification even if no “ dehumidification mode” point exists.

- Clockworks knows when to remove false positives based on inferred sequences. In other words, it doesn’t flag simultaneous heating and cooling when the unit should be simultaneously heating and cooling for dehumidification. The key here is that the rules within the FDD analysis are aware of each other. So if one rule invalidates another rule, the analysis knows to avoid the false positive. Classic examples are data quality checks. The system knows not to flag a leaking heating coil valve when the heating is not enabled, but rather flag it as sensor drift. Additionally, if one rule identifies a faulty sensor, it either stops the other rules that use that sensor from running or calls it out as a clear note where relevant. An example of this would be a static pressure sensor that drifted off calibration because the sensor is showing non-zero values when the fans are off in the middle of the night.

- Clockworks determines which possible causes to show and in which order based on related faults (leaking coil as possible cause to SAT above setpoint). Because the rules within an analysis are aware of each other, this means that possible causes can be listed in a dynamic way, providing critical root cause information based on what else has been identified.

—REQUEST A DEMO OF CLOCKWORKS’ BUILDING ANALYTICS SOFTWARE—

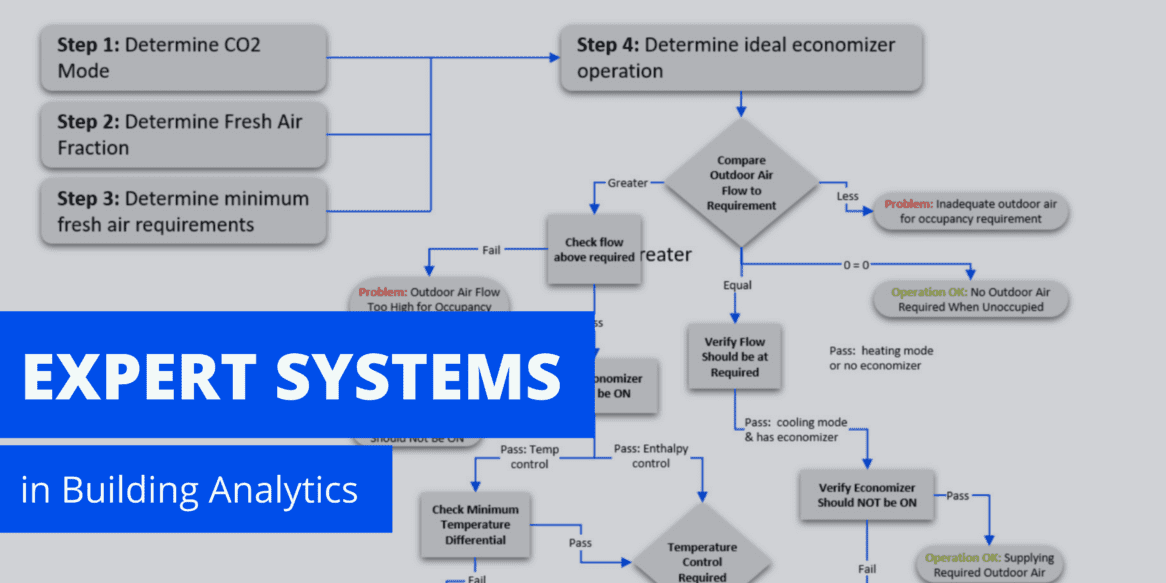

Example of an Expert System: The AHU Economizer Analysis

Next, let’s walk through an example of how one of our expert systems—the economizer analysis—is applied to an air handling unit (AHU).

The first step is to create the information model, which we covered in previous blog posts. An information model that is extensive enough to handle thousands of unique scenarios is essential to avoid one-off rule writing and run robust automated M&V.

This, combined with time series data, feeds into each individual expert system. As you can see below, the expert system is essentially a series of calculations, verifications, and checks running in a sequence.

As illustrated in “Tracking Air Temperature: The Clockworks Approach”, what initially seems simple, is actually not simple at scale. There are so many ways point information can determine if a space is occupied (occupancy status, command, schedule, mode, motion or infrared sensor, VAV airflow) and what the setpoint should be (single-sided, double-sided, heating or cooling setpoints). One can quickly see how an expert system is necessary to apply fault detection across the hundreds and thousands of scenarios these rules run into across a portfolio of buildings.

Let’s look closer at an expert system for an economizer analysis to illustrate the point.

Step 1: Determine CO2 Mode

The first step is to determine how the AHU adjusts ventilation rates based on measured CO2 levels in the building. This is an important check to understand if the economizer sequence can be overridden by the CO2 mode to prevent false positives from triggering.

The first check determines whether there is a native “CO2Mode” point from the BAS. If there isn’t, the expert system moves into inference and generates the CO2Mode based on the available points. If no relevant points are present, it determines the economizer won’t be overridden by a CO2 sequence.

Step 2: Determine Fresh Air Fraction

The next step is to calculate the percentage of fresh air being supplied to the areas served by the air handling unit. This should be a simple check—just take a look at the outside air damper position, right? Not so fast… 20% open on a damper may not actually mean 20% airflow due to damper curves, varying duct sizes, bypass loops, etc.

As you’ll see in the expert system checks below, Clockworks uses measured airflows and temperatures to accurately calculate the fresh air fraction while checking for bad sensor data which could produce additional false positives.

The left side of the tree checks to see whether the fraction can be completed using measured or calculated air flows and whether those flows are reliable. If they aren’t present or reliable the right side of the tree attempts to calculate the fresh air fraction using return, mixed, and outdoor air temperature sensor data.

Step 3: Determine Minimum Fresh Air Requirements

Once the fresh air fraction is known we need to compare it to the minimum fresh air requirements to maintain proper ventilation rates. The system needs to determine how the AHU maintains minimum airflow and what those requirements are based on.

As you can see, there are also nested expert systems that this analysis depends on, such as whether flow stations are reliable. Since they are notoriously unreliable, these embedded checks are vital to the integrity of the expert system.

Step 4: Determine Ideal Economizer Operation

The last step is to finally answer the question of “is my economizer operating correctly?” We combine the outputs from Steps 1 through 3 and complete our final checks to ensure the AHU economizer sequence is operating in an ideal state.

Our AHU Economizer analysis was born from research with PNNL in 2003 and has evolved to check for any condition disrupting ideal ventilation rates on an AHU. This is the same analysis that expert commissioning and controls engineers use when analyzing system performance manually. Embedding these engineering analyses into an FDD application allows facilities management personnel and service providers to efficiently scale their team and focus on what matters most – fixing the issues identified by the expert system analysis.

“Embedding these engineering analyses into an FDD application allows facilities management personnel and service providers to efficiently scale their team and focus on what matters most – fixing the issues identified by the expert system analysis.”

So, does Clockworks do A.I.?

Well, yes.

Sure, it might not be as splashy as the artificial intelligence involved in self-driving cars, robotics, voice assistance, facial recognition, or…Westworld. But it’s exactly what’s needed for enabling Fault Detection and Diagnostics at scale. Our Expert Systems, coupled with the Clockworks Information Model, provides the most accurate HVAC root-cause diagnostics on the market today. And they’re only getting smarter.