Unlocking the Full Potential of Condition-Based Asset Intelligence

December 15, 2025

Beyond Energy: How FDD is Transforming Facilities Management

Watch Clockworks Co-CEO Nick Gayeski discuss this topic at our annual Client Summit by viewing the clip below.

Facilities today face mounting challenges: rising costs, increased energy consumption, labor shortages, and aging infrastructure. The statistics are stark—one in four HVAC technician positions in the next four years are projected to go unfilled. With fewer people available to tackle these problems, organizations must leverage technology and process innovation to do more with less.

The good news? Fault Detection and Diagnostics (FDD) technology is proving to be a powerful solution, delivering measurable benefits across energy efficiency, maintenance optimization, asset life extension, and capital planning. But many organizations are only scratching the surface of what’s possible.

The MyChart Analogy: Your Building’s Health Record

Think of FDD like MyChart in healthcare. Just as MyChart provides lab results, X-rays, and MRI scans to create a comprehensive diagnostic record of patient health, FDD platforms like Clockworks create a diagnostic record of asset health. This asset health intelligence can inform decisions across every aspect of facilities management—not just energy and maintenance.

Six Key Value Streams

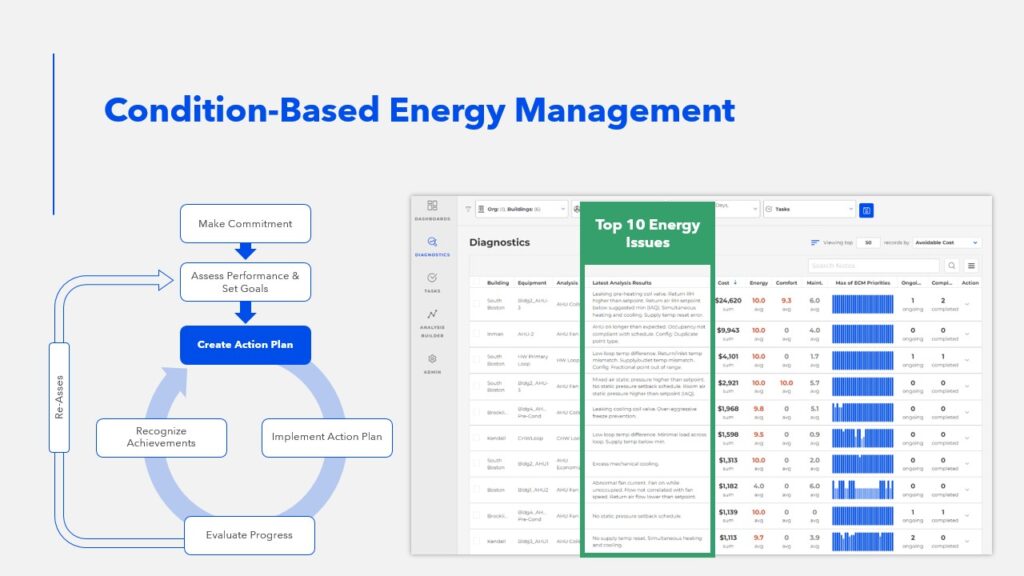

1. Condition-Based Energy Management

This is the familiar starting point for most organizations—using real-time asset data to identify energy waste, prioritize actions, and drive savings through data-driven decision-making rather than reactive responses to complaints or alarms.

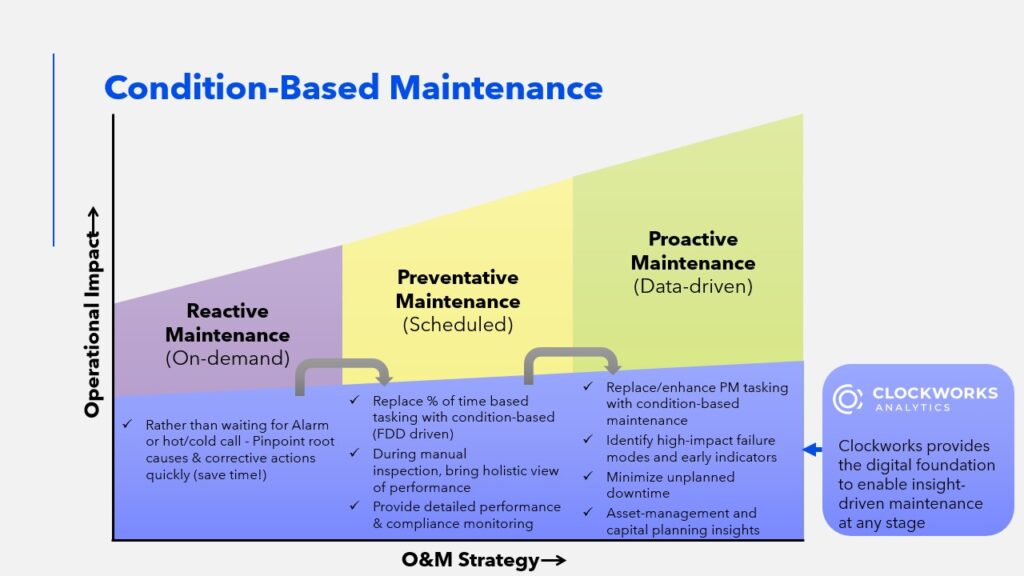

2. Condition-Based Maintenance

FDD empowers a comprehensive maintenance strategy that goes beyond traditional preventive maintenance:

- Repair on demand: For less critical assets, FDD provides early detection of issues before they become emergencies

- Condition-based interventions: Monitor degradation metrics like heat exchanger effectiveness or filter differential pressure to perform maintenance only when needed

- Predictive insights: While no one can predict exact failure times, FDD identifies combinations of problems that indicate higher failure risk

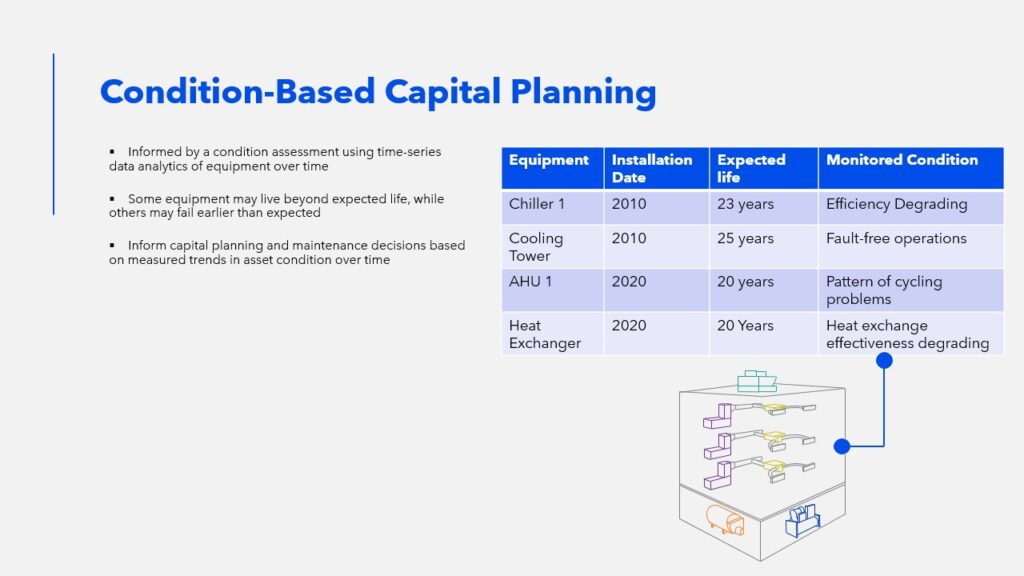

3. Condition-Based Capital Planning

Traditional capital planning relies on installation dates, expected life spans, and occasional condition assessments. But what if you had years of performance data on every asset? FDD provides:

- Fault prevalence tracking over multiple years

- Performance metrics (kW/ton for chillers, kW/CFM for fans)

- Runtime hours and recurring issue patterns

- Data-driven insights that far exceed walk-through assessments

This matters because capital costs dwarf annual energy and maintenance expenses. Better capital planning decisions can extend asset life and optimize replacement timing, delivering significant value to the organization.

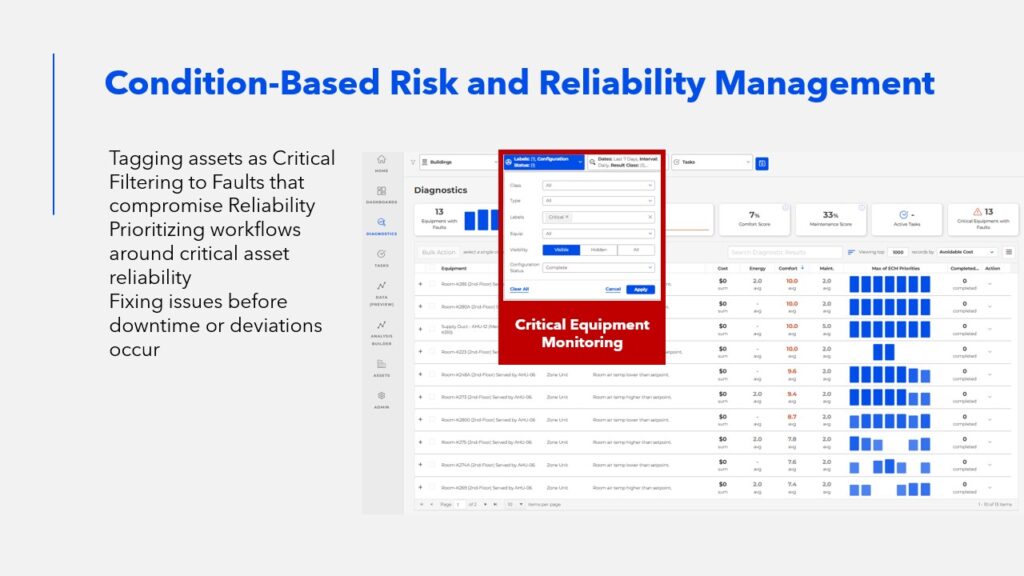

4. Risk and Reliability Management

For mission-critical facilities—hospitals, manufacturing plants, research labs—maintaining uptime is paramount. FDD enables:

- Critical equipment labeling and prioritization

- Focus on critical failures affecting core operations

- Proactive monitoring to prevent product loss and maintain quality spaces

- Direct alignment with organizational mission

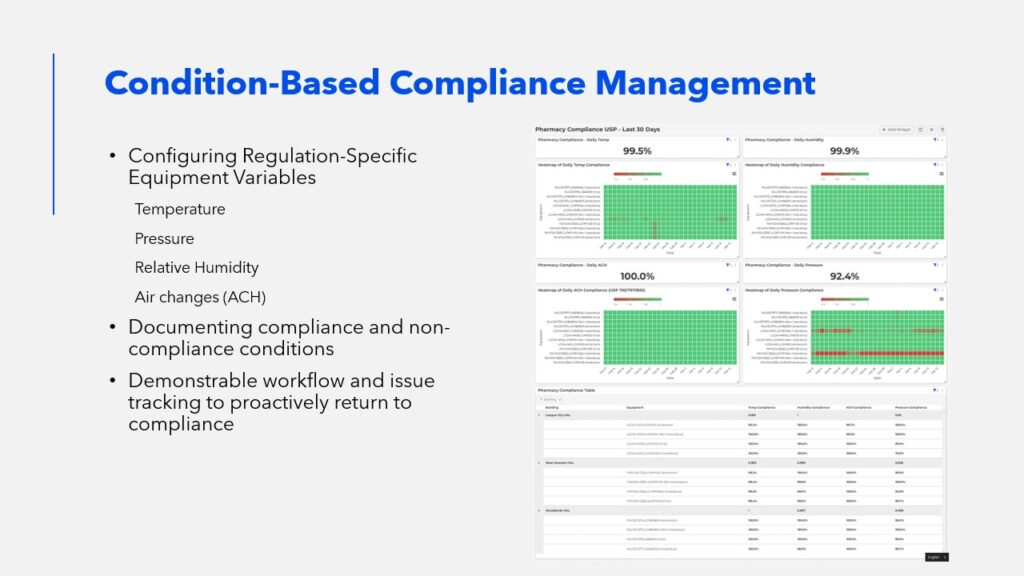

5. Compliance Management

Beyond maintaining reliability, FDD helps organizations demonstrate compliance to regulators and inspectors by:

- Recording continuous data on critical parameters

- Documenting escalation and resolution processes

- Creating transparent, exportable records

- Proving proactive, data-driven compliance management

6. Business Outcomes Alignment

Ultimately, success means connecting asset health to organizational mission—whether that’s educational outcomes, manufacturing efficiency, tenant satisfaction, or healthcare delivery. The trends and buzzwords may change, but the fundamental need to support the organization’s mission profitably and effectively remains constant.

The Path Forward

Organizations typically begin with FDD for energy optimization, but the relationship should evolve to unlock additional value streams over time. The key is making these programs accessible through:

- Standardized delivery: Clear processes and documentation for implementing programs like condition-based maintenance and compliance monitoring

- Lower barriers to entry: Reducing manual work and automating dashboard setup

- Program management: Dedicated focus on connecting product capabilities to customer value

- Benchmarking: Leveraging anonymized data from hundreds of thousands of assets to compare performance against peers

Getting Started

The journey begins with connecting buildings and optimizing performance, but that’s just the foundation. By expanding FDD into maintenance management, compliance, capital planning, and beyond, organizations can:

- Extend asset life and demonstrate maintenance team value

- Make smarter capital decisions based on actual performance data

- Reduce risk and improve reliability for critical operations

- Demonstrate compliance proactively

- Align facilities investments with organizational mission

The data is already there in your buildings. The question is: how will you unlock its full potential?

Interested in learning more about condition-based asset intelligence and how it can transform your facilities management program? Contact us today!

Back to blog