How a Pharmaceutical Facility Achieved €500K Energy Savings with Building Analytics

August 26, 2025

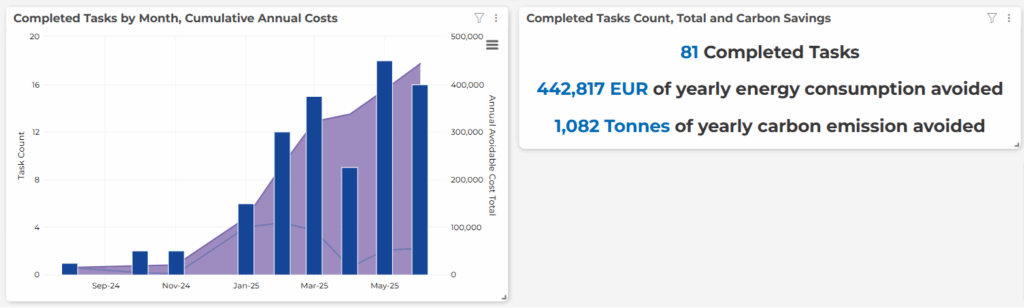

Facilities managers in pharmaceutical manufacturing face unique challenges balancing energy efficiency with strict operational requirements while coordinating efforts across multiple teams and complex building systems. This case study demonstrates how one leading pharmaceutical facility exceeded their annual energy savings goal by 67% while streamlining maintenance operations and building performance optimization across four buildings.

Facilities Management Challenge: Coordinating Multi-Team Energy Initiatives

A leading pharmaceutical company with a site in Singapore set an ambitious internal goal of saving €300,000 annually through improved building energy management and facilities maintenance workflow optimization. The site’s complex infrastructure presented significant coordination challenges:

Multi-Building Operations: Four buildings requiring integrated energy management systems and consistent maintenance protocols across diverse spaces and equipment.

Cross-Functional Teams: Two distinct operational groups—the Production Maintenance team focused on manufacturing equipment and the Utilities team managing building systems—needed aligned energy efficiency strategies while maintaining their specialized focus areas.

Scalable Solutions Required: With ambitious energy savings targets and pharmaceutical-grade operational requirements, the facility needed a scalable solution to streamline diagnostics, prioritize maintenance, and track progress.

Building Analytics Solution for Pharmaceutical Facilities

Since connecting to Clockworks Analytics in September, the facility began actively implementing data-driven building performance optimization by October. Led by Jan Zajas, Clockworks’ Consulting Services Engineer, the teams developed a structured approach to facilities management software implementation and energy efficiency optimization.

Targeted Team Engagement: Recognizing that effective facilities operations require respect for each team’s specialized expertise, Jan restructured regular meetings to be building-specific and team-focused. Rather than broad general sessions, he created targeted meetings for the Production Maintenance team and Utilities team separately, ensuring each group received relevant insights and actionable maintenance management tasks aligned with their operational priorities.

User Adoption and Platform Mastery: The teams rapidly became power users of the building analytics platform, with over 20 active users regularly checking and updating maintenance tasks. This high engagement level demonstrated the transition from external dependency to internal ownership—teams moved from relying on outside support to independently creating and managing tasks while leveraging their deep knowledge of building systems.

Integration with Existing Workflows: The facility successfully integrated Clockworks with their existing work order system, creating streamlined maintenance workflows that enhanced rather than disrupted established pharmaceutical facility operations.

Measurable Results: Energy Savings and Operational Efficiency

Exceeded Energy Savings Goals: The facility achieved approximately €500,000 in energy savings, surpassing their initial €300,000 target—demonstrating the ROI potential of data-driven facilities management.

High Team Engagement: With the highest platform usage across their organization, the Singapore team exemplifies how internal ownership and proper change management drive facilities management success.

Streamlined Operations: By maintaining organized task environments and integrating building analytics with existing maintenance management systems, the teams created more efficient operational workflows that support both energy goals and pharmaceutical operational requirements.

Data-Driven Decision Making: The facility is now creating custom dashboards within the Clockworks platform, establishing building analytics as their central hub for energy management and maintenance insights.

Sustained Facilities Performance Optimization

The Singapore facility plans to continue advancing their building performance optimization through condition-based maintenance and predictive maintenance strategies. With ongoing support from the company’s Singapore site Program Manager and continued guidance from Jan Zajas through a Professional Services contract, the team has established sustainable practices for long-term energy management success.

This pharmaceutical facilities case study demonstrates how the right combination of building analytics technology, targeted team engagement, and systematic implementation can deliver measurable energy efficiency results while enhancing overall facilities operations.

Back to resources